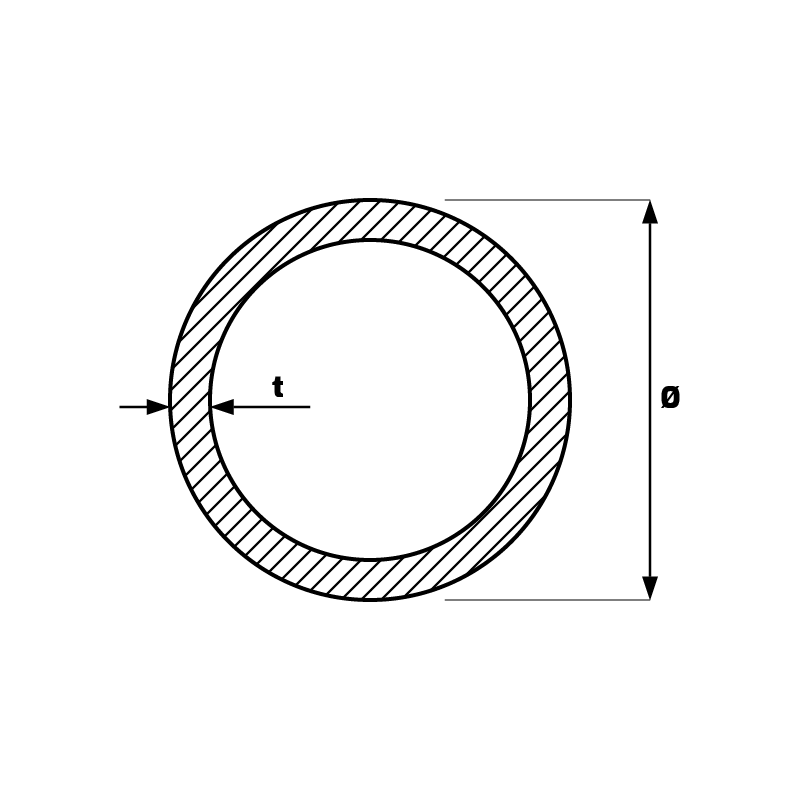

Galvanized steel pipe for instalation

SR EN 10255

SR EN 10255

Fields of application

Galvanised pipes made from carbon steel, longitudinal welded, with zinc coating are destined for cold and hot water transport networks, for heating installations (where the pressure does not exceed 50 bars), also for tehnological installations. The superior quality of the used material, allows to estimate a minimum lifespan for the product of 15 years, respecting the proper anticorrosion protection measures.