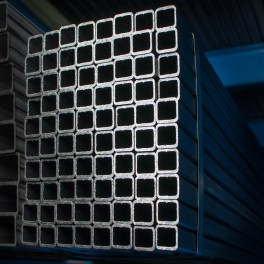

Square precission steel tube

SR EN 10219-2

SR EN 10219-2

Fields of application

Are used in machine construction, where technical conditions need to be met, also for general uses.

SR EN 10219-2

SR EN 10219-2

Are used in machine construction, where technical conditions need to be met, also for general uses.

The exterior and interior surfaces of the pipe must be smooth, without fissures, cracks, overlay of materials, non-metallic inclusions. Small scratches, bumps, dents, a thin layer of welding cinder or traces after clearing defects resulting from the production process are allowed, avoiding wall thickness to fall under the minimal allowed limits. The welding seam needs to be compact and continuous, without fissures or other defects that reduce the rezistence of the seam under the rezistence of the base metal.

The exterior ledge of the welding seam is removed. Thickening of the seam within the range of permitted diameter limits is allowed. The interior burr of the welding seam is not removed. Unevenness on the margins of the metal strip in the welding seam is not allowed. Extremities of the pipe must be cut perpendicularly on its' axis. A burr on the pipe ends resulting from the tehnologic process of cutting is allowed. Deformation of pipe ends is not allowed.

The steel sections are not treated after the cold-rolling. On the external and internal surface, there can appear tracks of emulsion, respectively smaller tracks of oxidation. On the external surfaces of the sections there is applied an oil covering, that assures a provisional protection against corrosion. At request one can renounce to this protection covering.

| Size (mm) | Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 20 x 20 | 2 | 1.05 |

| 25 x 25 | 2 | 1.36 |

| 30 x 30 | 2 | 1.68 |

| 40 x 40 | 2 | 2.31 |

| 50 x 50 | 2 | 2.98 |

| 60 x 60 | 2 | 3.56 |

| 20 x 20 | 2.5 | 1.64 |

| 25 x 25 | 2.5 | 1.64 |

| 30 x 30 | 2.5 | 2.3 |

| 40 x 40 | 2.5 | 2.82 |

| 50 x 50 | 2.5 | 3.6 |

| 60 x 60 | 2.5 | 4.39 |

| 70 x 70 | 2.5 | 5.17 |

| 25 x 25 | 3 | 1.89 |

| 30 x 30 | 3 | 2.36 |

| 40 x 40 | 3 | 3.3 |

| 50 x 50 | 3 | 3.25 |

| 60 x 60 | 3 | 5.16 |

| 70 x 70 | 3 | 6.13 |

| 80 x 80 | 3 | 7.07 |

| 90 x 90 | 3 | 8.1 |

| 100 x 100 | 3 | 8.96 |

| 40 x 40 | 4 | 4.2 |

| 50 x 50 | 4 | 5.45 |

| 70 x 70 | 4 | 7.94 |

| 80 x 80 | 4 | 9.2 |

| 90 x 90 | 4 | 10.5 |

| 100 x 100 | 4 | 11.7 |

| 50 x 50 | 5 | 6.56 |

| 70 x 70 | 5 | 9.7 |

| 80 x 80 | 5 | 11.3 |

| 90 x 90 | 5 | 12.8 |

| SE EN 10025-2:2004 | State | Thickness | Rm N/mm2 | Rp 0,2 | A5 (%) | Weldability |

|---|---|---|---|---|---|---|

| S235JRG2 | <16 | 340-470 | 235 | 24 | excellent | |

| 16-40 | 340-470 | 225 | 24 | excellent | ||

| 40-63 | 340-470 | 215 | 23 | excellent | ||

| 63-80 | 340-470 | 215 | 22 | excellent | ||

| 80-100 | 340-470 | 215 | 22 | excellent | ||

| 100-150 | 340-470 | 195 | 22 | excellent | ||

| 150-200 | 320-470 | 185 | 21 | excellent | ||

| 200-250 | 320-470 | 175 | 21 | excellent |

| S235JRG2 | C | Si | Mn | Ni | P | S | Cr | Mo | Al | Cr+Mo+Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| max 0.2 | max 0.55 | max 1.4 | max 0.3 | max 0.045 | max 0.045 | max 0.3 | max 0.08 | min 0.02 | 0.48 |

The standard size at which these steel profiles are delivered is 6000 mm.

In the case of sheets you can buy whole pieces!