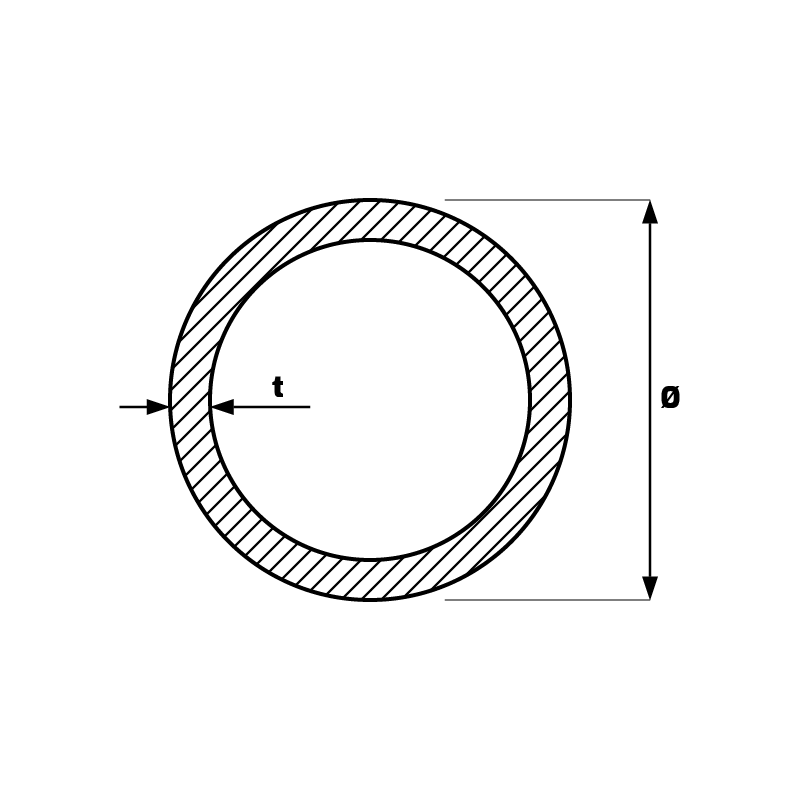

Precission steel tube

SR EN 10305-3

SR EN 10305-3

Fields of usage

Are used in machine construction, where technical conditions need to be met, also for general uses.

SR EN 10305-3

SR EN 10305-3

Are used in machine construction, where technical conditions need to be met, also for general uses.

The exterior and interior surfaces of the pipes must be smooth, corresponding to the fabrication procedure.

The pipes' inner and outer surfices must not show fissures, overlays of material, bubbles, non-metallic inclusions or other defects visible with the naked eye. Small bumps, dents, jags and traces from cleaning surface defects, with the condition that the deepness of these will not exceed the negative tolerance of the wall thickness. For pipes with an inner diameter under 15 mm smoothness of the interior surface is not guaranteed.

The pipes are delivered with cold hardening or heat treatment. Those with heat treatment (normalized) are delivered with oxides formed in the technological process of manufacturing. At request they can be delivered also in other terms of the surface aspect (normalized in neutral atmosphere N.A.N. pickled, etc.)

| Diameter Ø (mm) | Thickness t (mm) | Weight (kg/m) |

|---|---|---|

| 13 | 0.7 | 0.21 |

| 16 | 0.7 | 0.27 |

| 18 | 0.7 | 0.30 |

| 19 | 0.7 | 0.32 |

| 20 | 0.7 | 0.33 |

| 22 | 0.7 | 0.37 |

| 25 | 0.7 | 0.42 |

| 28 | 0.7 | 0.47 |

| 29 | 0.7 | 0.48 |

| 30 | 0.7 | 0.51 |

| 32 | 0.7 | 0.54 |

| 13 | 0.8 | 0.24 |

| 16 | 0.8 | 0.30 |

| 18 | 0.8 | 0.34 |

| 19 | 0.8 | 0.36 |

| 20 | 0.8 | 0.38 |

| 21 | 0.8 | 0.35 |

| 22 | 0.8 | 0.42 |

| 25 | 0.8 | 0.48 |

| 28 | 0.8 | 0.55 |

| 29 | 0.8 | 0.55 |

| 30 | 0.8 | 0.58 |

| 32 | 0.8 | 0.62 |

| 35 | 0.8 | 0.67 |

| 38 | 0.8 | 0.73 |

| 40 | 0.8 | 0.77 |

| 42 | 0.8 | 0.81 |

| 13 | 0.9 | 0.27 |

| 16 | 0.9 | 0.34 |

| 18 | 0.9 | 0.38 |

| 19 | 0.9 | 0.41 |

| 20 | 0.9 | 0.42 |

| 21 | 0.9 | 0.40 |

| 22 | 0.9 | 0.47 |

| 25 | 0.9 | 0.54 |

| 28 | 0.9 | 0.60 |

| 29 | 0.9 | 0.61 |

| 30 | 0.9 | 0.65 |

| 32 | 0.9 | 0.69 |

| 35 | 0.9 | 0.76 |

| 38 | 0.9 | 0.82 |

| 40 | 0.9 | 0.87 |

| 42 | 0.9 | 0.91 |

| 45 | 0.9 | 0.98 |

| 48 | 0.9 | 1.04 |

| 51 | 0.9 | 1.11 |

| 13 | 1 | 0.30 |

| 16 | 1 | 0.37 |

| 18 | 1 | 0.42 |

| 19 | 1 | 0.44 |

| 20 | 1 | 0.47 |

| 21 | 1 | 0.45 |

| 22 | 1 | 0.51 |

| 25 | 1 | 0.59 |

| 28 | 1 | 0.67 |

| 29 | 1 | 0.68 |

| 30 | 1 | 0.72 |

| 32 | 1 | 0.77 |

| 35 | 1 | 0.84 |

| 38 | 1 | 0.91 |

| 40 | 1 | 0.96 |

| 42 | 1 | 1.03 |

| 45 | 1 | 1.09 |

| 48 | 1 | 1.16 |

| 51 | 1 | 1.23 |

| 13 | 1.2 | 0.35 |

| 16 | 1.2 | 0.44 |

| 18 | 1.2 | 0.50 |

| 19 | 1.2 | 0.53 |

| 20 | 1.2 | 0.56 |

| 21 | 1.2 | 0.49 |

| 22 | 1.2 | 0.62 |

| 25 | 1.2 | 0.70 |

| 28 | 1.2 | 0.79 |

| 29 | 1.2 | 0.81 |

| 30 | 1.2 | 0.85 |

| 32 | 1.2 | 0.91 |

| 35 | 1.2 | 1.00 |

| 38 | 1.2 | 1.09 |

| 40 | 1.2 | 1.15 |

| 42 | 1.2 | 1.21 |

| 45 | 1.2 | 1.30 |

| 48 | 1.2 | 1.41 |

| 50 | 1.2 | 1.44 |

| 51 | 1.2 | 1.47 |

| 57 | 1.2 | 1.65 |

| 60 | 1.2 | 1.74 |

| 63 | 1.2 | 1.83 |

| 70 | 1.2 | 2.04 |

| 72 | 1.2 | 2.09 |

| 76 | 1.2 | 2.21 |

| 16 | 1.5 | 0.54 |

| 18 | 1.5 | 0.61 |

| 19 | 1.5 | 0.65 |

| 20 | 1.5 | 0.68 |

| 21 | 1.5 | 0.59 |

| 22 | 1.5 | 0.76 |

| 25 | 1.5 | 0.87 |

| 27 | 1.5 | 0.94 |

| 28 | 1.5 | 0.98 |

| 29 | 1.5 | 1.00 |

| 30 | 1.5 | 1.05 |

| 32 | 1.5 | 1.13 |

| 34 | 1.5 | 1.20 |

| 35 | 1.5 | 1.24 |

| 38 | 1.5 | 1.35 |

| 40 | 1.5 | 1.42 |

| 42 | 1.5 | 1.50 |

| 45 | 1.5 | 1.61 |

| 48 | 1.5 | 1.72 |

| 50 | 1.5 | 1.79 |

| 51 | 1.5 | 1.83 |

| 57 | 1.5 | 2.05 |

| 60 | 1.5 | 2.16 |

| 63 | 1.5 | 2.27 |

| 70 | 1.5 | 2.53 |

| 72 | 1.5 | 2.61 |

| 76 | 1.5 | 2.76 |

| 83 | 1.5 | 3.01 |

| 89 | 1.5 | 3.24 |

| 96 | 1.5 | 3.49 |

| 21 | 2 | 0.72 |

| 22 | 2 | 0.99 |

| 25 | 2 | 1.13 |

| 27 | 2 | 1.23 |

| 28 | 2 | 1.28 |

| 29 | 2 | 1.31 |

| 30 | 2 | 1.28 |

| 32 | 2 | 1.48 |

| 34 | 2 | 1.58 |

| 35 | 2 | 1.63 |

| 38 | 2 | 1.77 |

| 40 | 2 | 1.87 |

| 42 | 2 | 1.97 |

| 45 | 2 | 2.12 |

| 48 | 2 | 2.27 |

| 50 | 2 | 2.37 |

| 51 | 2 | 2.42 |

| 57 | 2 | 2.71 |

| 60 | 2 | 2.86 |

| 63 | 2 | 3.01 |

| 70 | 2 | 3.35 |

| 72 | 2 | 3.45 |

| 76 | 2 | 3.65 |

| 83 | 2 | 3.99 |

| 89 | 2 | 4.29 |

| 96 | 2 | 4.63 |

| 102 | 2 | 4.93 |

| 108 | 2 | 5.23 |

| 114 | 2 | 5.52 |

| 21 | 2.5 | 0.94 |

| 27 | 2.5 | 1.51 |

| 32 | 2.5 | 1.82 |

| 34 | 2.5 | 1.94 |

| 35 | 2.5 | 2.00 |

| 38 | 2.5 | 2.19 |

| 40 | 2.5 | 2.31 |

| 42 | 2.5 | 2.44 |

| 45 | 2.5 | 2.62 |

| 48 | 2.5 | 2.81 |

| 50 | 2.5 | 2.93 |

| 51 | 2.5 | 2.99 |

| 57 | 2.5 | 3.35 |

| 60 | 2.5 | 3.54 |

| 63 | 2.5 | 3.73 |

| 70 | 2.5 | 4.16 |

| 72 | 2.5 | 4.28 |

| 76 | 2.5 | 4.53 |

| 83 | 2.5 | 4.96 |

| 89 | 2.5 | 5.33 |

| 96 | 2.5 | 5.76 |

| 102 | 2.5 | 6.13 |

| 108 | 2.5 | 6.50 |

| 114 | 2.5 | 6.87 |

| 27 | 3 | 1.78 |

| 34 | 3 | 2.29 |

| 35 | 3 | 2.37 |

| 38 | 3 | 2.59 |

| 40 | 3 | 2.74 |

| 42 | 3 | 2.89 |

| 45 | 3 | 3.11 |

| 48 | 3 | 3.33 |

| 50 | 3 | 3.48 |

| 51 | 3 | 3.55 |

| 57 | 3 | 3.99 |

| 60 | 3 | 4.22 |

| 63 | 3 | 4.44 |

| 70 | 3 | 4.95 |

| 72 | 3 | 5.10 |

| 76 | 3 | 5.40 |

| 83 | 3 | 5.92 |

| 89 | 3 | 6.36 |

| 96 | 3 | 6.88 |

| 102 | 3 | 7.32 |

| 108 | 3 | 7.76 |

| 114 | 3 | 8.21 |

| 42 | 3.5 | 3.32 |

| 45 | 3.5 | 3.58 |

| 48 | 3.5 | 3.84 |

| 50 | 3.5 | 4.01 |

| 51 | 3.5 | 4.10 |

| 57 | 3.5 | 4.62 |

| 60 | 3.5 | 4.87 |

| 63 | 3.5 | 5.13 |

| 70 | 3.5 | 5.74 |

| 72 | 3.5 | 5.91 |

| 76 | 3.5 | 6.26 |

| 83 | 3.5 | 6.86 |

| 89 | 3.5 | 7.38 |

| 96 | 3.5 | 7.98 |

| 102 | 3.5 | 8.50 |

| 108 | 3.5 | 9.02 |

| 114 | 3.5 | 9.53 |

| 42 | 4 | 3.75 |

| 45 | 4 | 4.04 |

| 48 | 4 | 4.39 |

| 50 | 4 | 4.54 |

| 51 | 4 | 4.63 |

| 57 | 4 | 5.23 |

| 60 | 4 | 5.52 |

| 63 | 4 | 5.82 |

| 70 | 4 | 6.51 |

| 72 | 4 | 6.71 |

| 76 | 4 | 7.10 |

| 83 | 4 | 7.79 |

| 89 | 4 | 8.38 |

| 96 | 4 | 9.07 |

| 102 | 4 | 9.67 |

| 108 | 4 | 10.25 |

| 114 | 4 | 10.85 |

| 48 | 5 | 5.30 |

| 50 | 5 | 5.55 |

| 51 | 5 | 5.70 |

| 57 | 5 | 6.41 |

| 60 | 5 | 6.79 |

| 63 | 5 | 7.15 |

| 70 | 5 | 8.01 |

| 72 | 5 | 8.26 |

| 76 | 5 | 8.75 |

| 83 | 5 | 9.61 |

| 89 | 5 | 10.35 |

| 96 | 5 | 11.22 |

| 102 | 5 | 11.96 |

| 108 | 5 | 12.69 |

| 114 | 5 | 13.43 |

| SE EN 10025-2:2004 | State | Thickness | Rm N/mm2 | Rp 0,2 | A5 (%) | Weldability |

|---|---|---|---|---|---|---|

| S235JRG2 | <16 | 340-470 | 235 | 24 | excellent | |

| 16-40 | 340-470 | 225 | 24 | excellent | ||

| 40-63 | 340-470 | 215 | 23 | excellent | ||

| 63-80 | 340-470 | 215 | 22 | excellent | ||

| 80-100 | 340-470 | 215 | 22 | excellent | ||

| 100-150 | 340-470 | 195 | 22 | excellent | ||

| 150-200 | 320-470 | 185 | 21 | excellent | ||

| 200-250 | 320-470 | 175 | 21 | excellent |

| S235JRG2 | C | Si | Mn | Ni | P | S | Cr | Mo | Al | Cr+Mo+Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| max 0.2 | max 0.55 | max 1.4 | max 0.3 | max 0.045 | max 0.045 | max 0.3 | max 0.08 | min 0.02 | max 0.48 |

The standard size at which these steel profiles are delivered is 6000 mm.

In the case of sheets you can buy whole pieces!